It is a long-established method for mooring analysis, and is described, for instance, in Bureau Veritas NR 493.

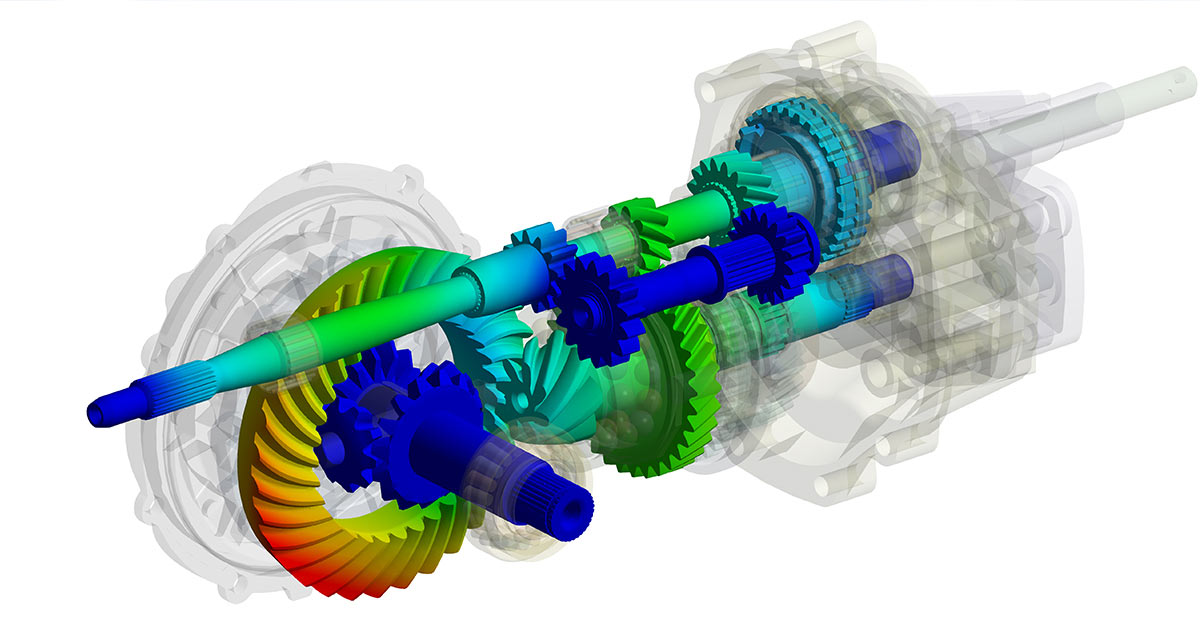

This form of analysis is known generally as quasi-dynamic analysis. Often, the interest lies only in the vessel and the finer details of the forces acting within the mooring lines are irrelevant: all that matters is to obtain a realistic approximation of the forces applied by the mooring lines to the vessel. This is just one application of our advanced fatigue assessment services.For many applications, such as modelling mooring lines attached to a vessel, the accuracy of the full finite element representation of the line, whereby it is discretised into individual nodes that each carry degrees of freedom, is not required. dents), we can use high-resolution ILI geometry data and our FE-DAT software to generate real feature-specific SCFs and calculate remaining life. For geometric deformations in pipelines (i.e. ROSEN can use these assessment methods to assess all types of components, either deterministically or using probabilistic methods. For cracks, a fracture mechanics growth assessment is often completed, but for other components and defects, a S-N approach can be taken, where a stress concentration factor is determined, and a stress range and frequency calculated and compared to applicable remaining life (S-N) curves. Different techniques can be used to calculate the impact of fatigue. Understanding the amount of fatigue damage accrued over time is critical in identifying when remedial action should be taken. However, if these defects are expensive to access for repair, or if repair requires the stoppage of operations, it can be far more cost-effective to conduct a more detailed analysis to show they are acceptable.Īssets are exposed to cyclic loading throughout their operational life, which causes fatigue damage to components and defects.

Sometimes, defects are deemed unacceptable by assessment methods that are overly conservative because of their simplicity. All of these require careful and considered analysis before the correct assessment pathway can be established. However, some defects are complex to assess examples include cracks in the door of a micro scrubber, multiple planar girth weld defects in a complex piping system and subsea pipeline buckles subject to Vortex Induced Vibrations (VIV). Often, defects are common, relatively uncomplex and can therefore be assessed using well-established and simple-to-use methodologies. Defects can manifest in a variety of differently shaped structures, such as tanks, piping systems, pressure vessels and pipelines, which all have different fabrication and manufacturing characteristics.

0 kommentar(er)

0 kommentar(er)